Our Journey

Aughton Automation was established in 1969, the year before The Beatles broke up.

-

1969

Aughton was established in January by Ted & Pat Kelly, working from their kitchen table! Initially, they began providing refurbished instrumentation for sale or hire to the oil & gas and petrochemical markets.

-

1970

Aughton attends trade exhibitions and acquires workshop facilities courtesy of Petrolite Ltd in Kirkby, whilst adding electrical & instrument maintenance to the services offered.

-

1971

Aughton adds Brewing to its target markets. These panels were designed, installed and commissioned for Greenall Whitley.

-

1972

A shortage of instrumentation skills in the UK prompts Aughton to provide training for established Craftsmen (mainly electricians and pipe fitters) to become instrument technicians and instrument mechanics.

-

1973

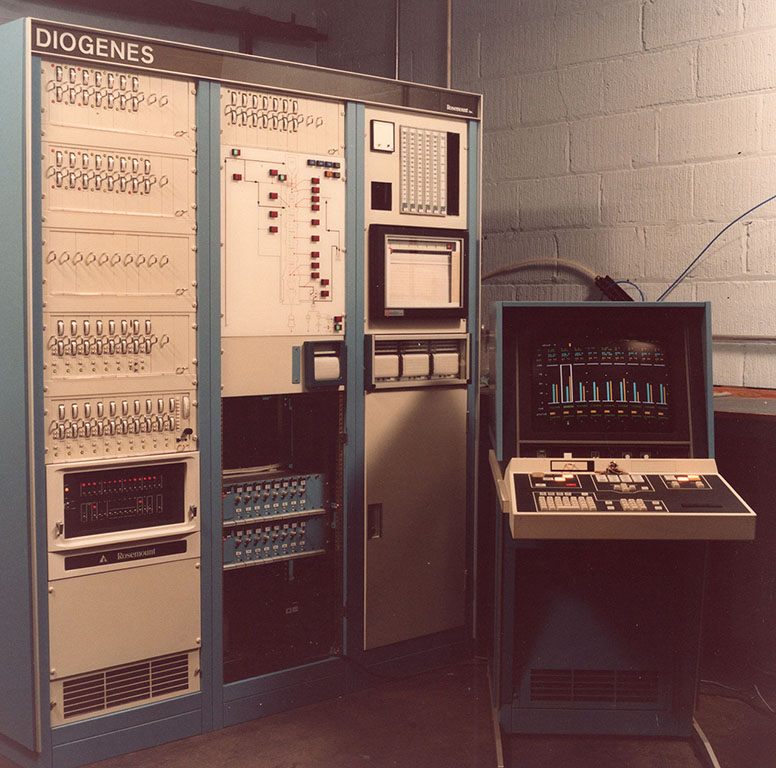

Aughton commissions Diogenes – the first dedicated electronic digital controllers to have multiple, selectable, fixed-equation algorithms for control of continuous and batch processes.

-

1974

Aughton enters the “environmental market”, years before ISO14001 is even a concept!

-

1975

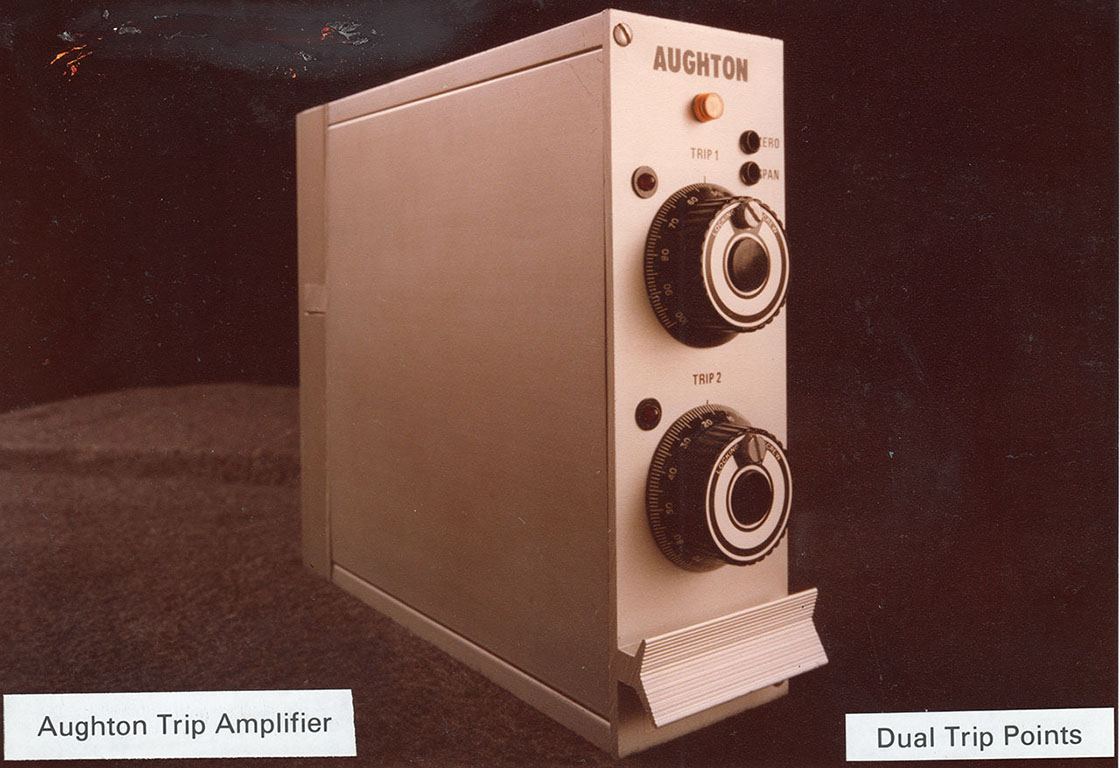

Aughton designs and manufactures its own brand of instrumentation.

-

1976

Aughton invests in a Motor Fleet comprising of two vans.

-

1977

The Commodore PET becomes the Aughton choice for industrial process control applications. This was innovative at the time; not many engineers had ever seen a “Personal Electronic Transactor” before.

-

1978

Aughton expand their offices & workshops in Kirkby to accommodate business growth. Tom King (3rd from left, later to become Lord King of Bridgwater), is greeted by Ted Kelly (4th from left) before touring the premises and meeting the staff.

-

1979

Participation at major exhibitions and trade fairs becomes a routine part of Aughton’s marketing strategy (and it gave some of the staff a good day out!).

-

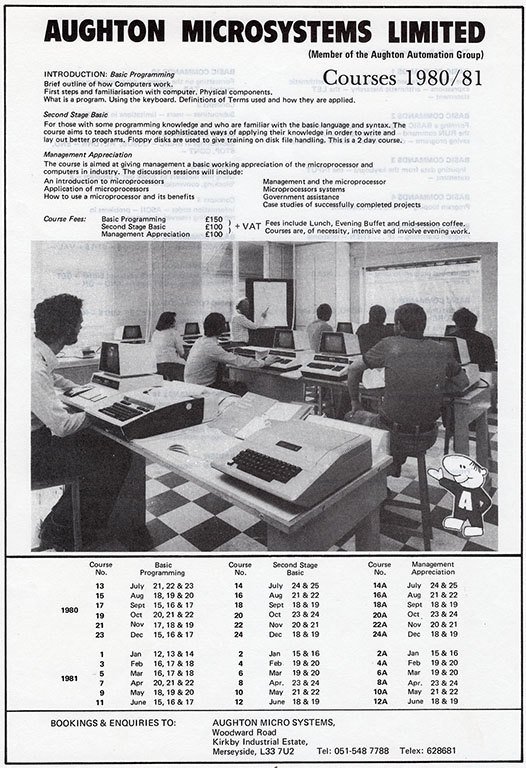

1980

In tandem with design and install projects, Aughton provides training for engineers and technicians in the latest process applications. Look at those prices!!!

-

1981

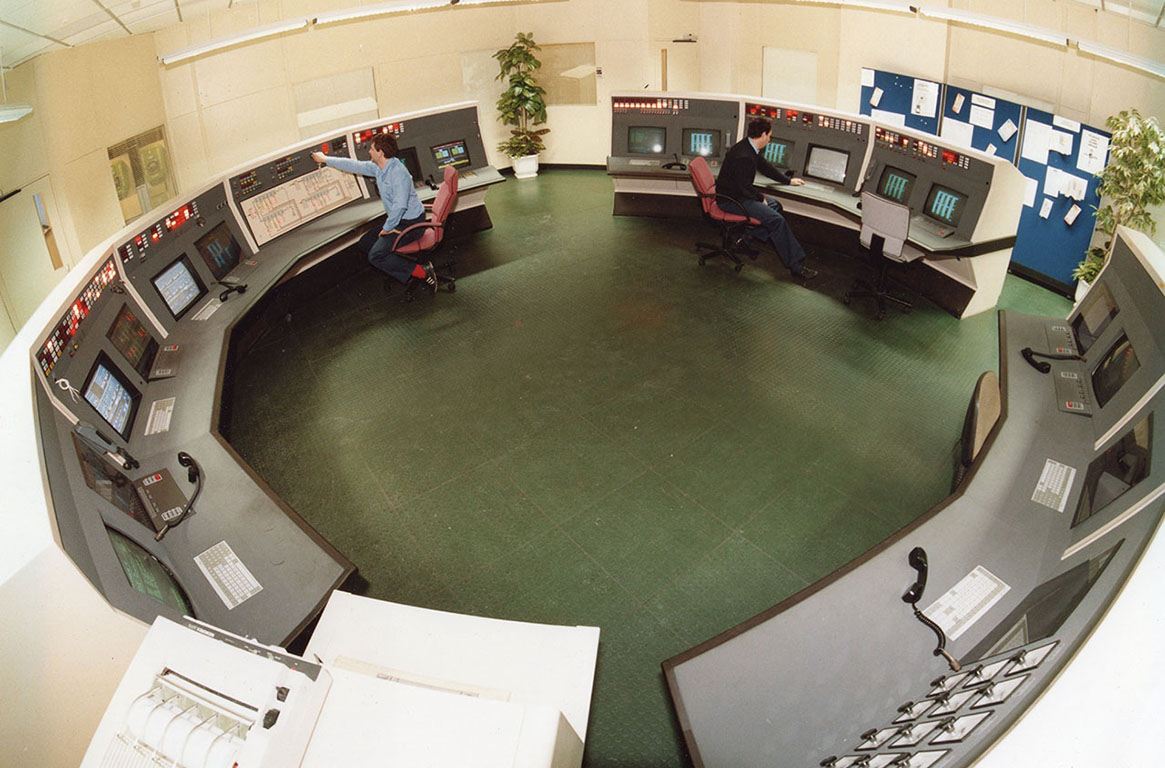

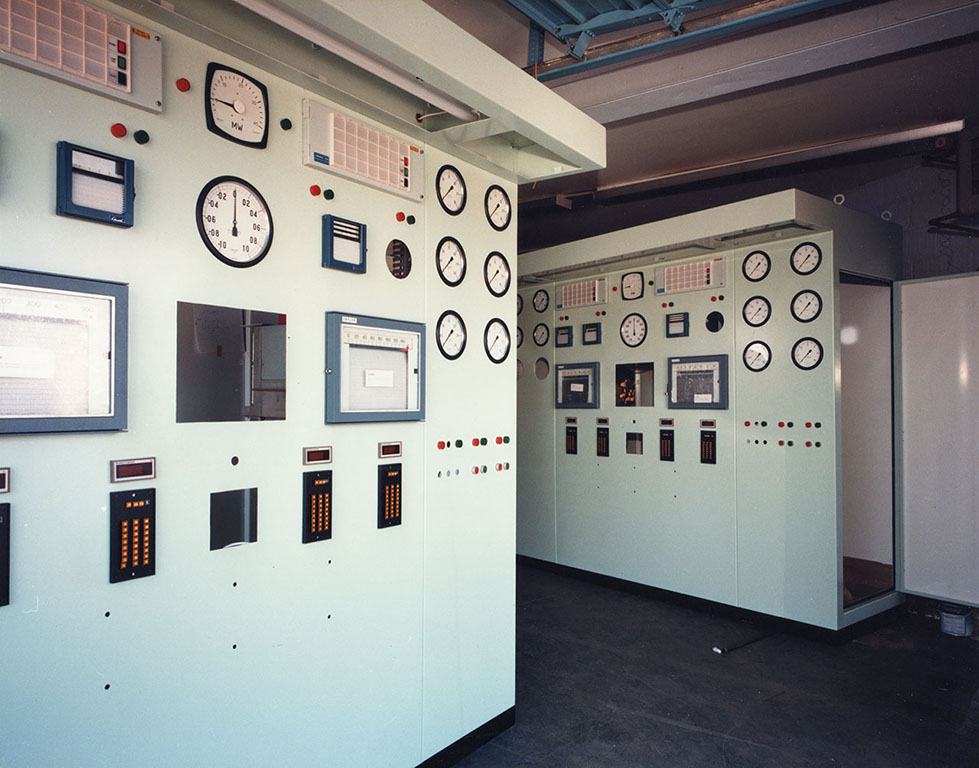

Aughton complete the upgrade of the new, high-tech main control room for Mobil Oil.

-

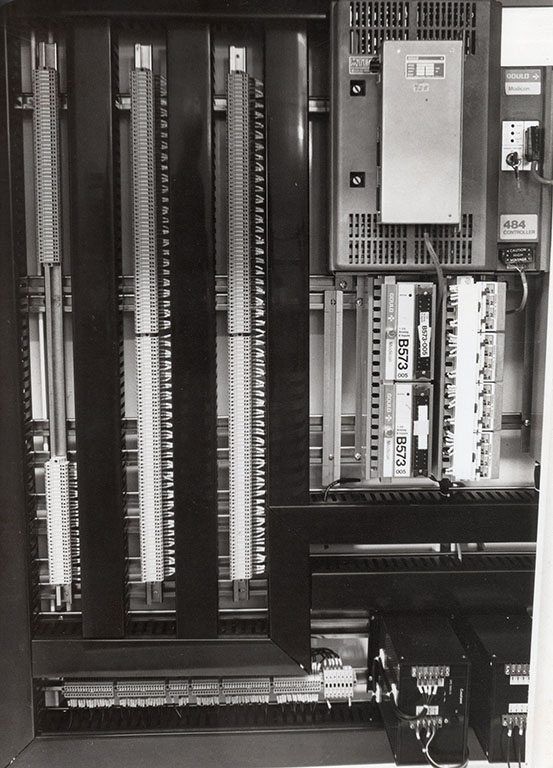

1982

Gould Modicon PLC’s were the Aughton choice to automate the silica gel plant at Crosfield Chemicals.

-

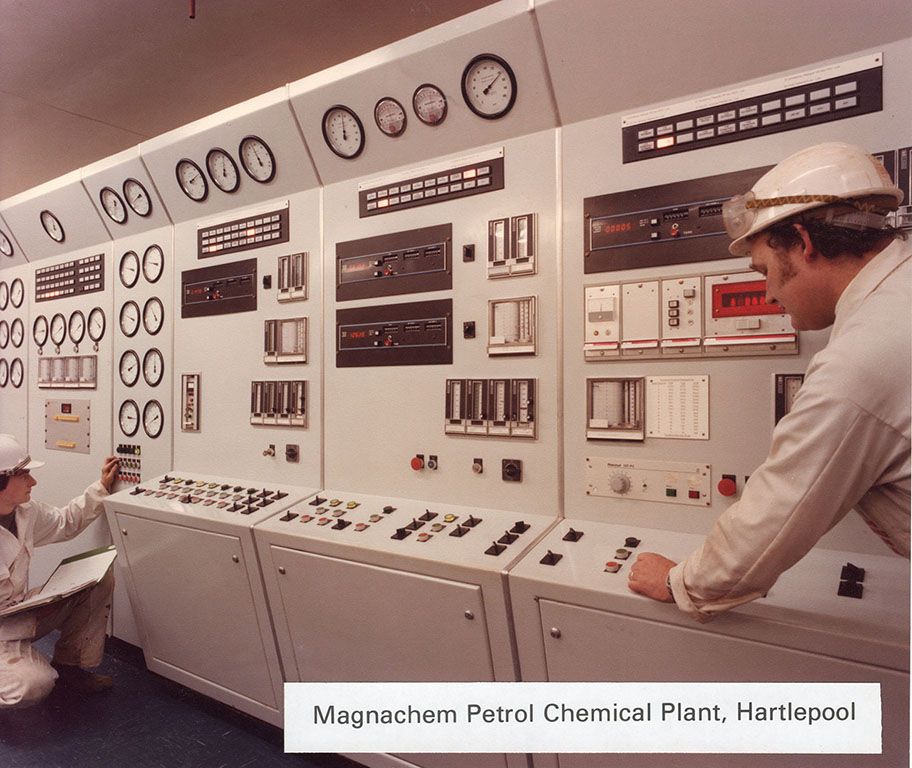

1983

Aughton designs, manufactures, installs, and commissions the new facility at Magnachem. Every loop works first time.

-

1984

Aughton designs and supplies the control desks for the re-build of the bulk fuel tank farm at Mount Pleasant Airport in the Falkland Islands.

-

1985

Aughton develops interfaces for the new, revolutionary Apple Mac computer, launched by Steve Jobs the previous year.

-

1986

Automation of three major breweries in the UK is achieved by Aughton engineers while introducing innovate techniques to resolve historical problems.

-

1987

Texas Instruments was specified by ICI for Aughton to design and install a “state of the art” system for the Works Instrument Air Compressors.

-

1988

Alan Faulkner completes the design for a Control Mimic to be installed at Faslane nuclear submarine base. This was Alan’s last job for Aughton before he left to start Priory Design, followed by Millbank Holdings.

-

1989

Aughton carries out a total rewire and upgrade of the control systems on Press Line 45, for the Ford motor company at the Halewood plant (now Jaguar-Land Rover). It was the first time a press line had been refurbished on-time and within budget (it also worked on start-up).

-

1990

There was no shortage of Aughton engineers or technicians who wanted to be involved with this project.

-

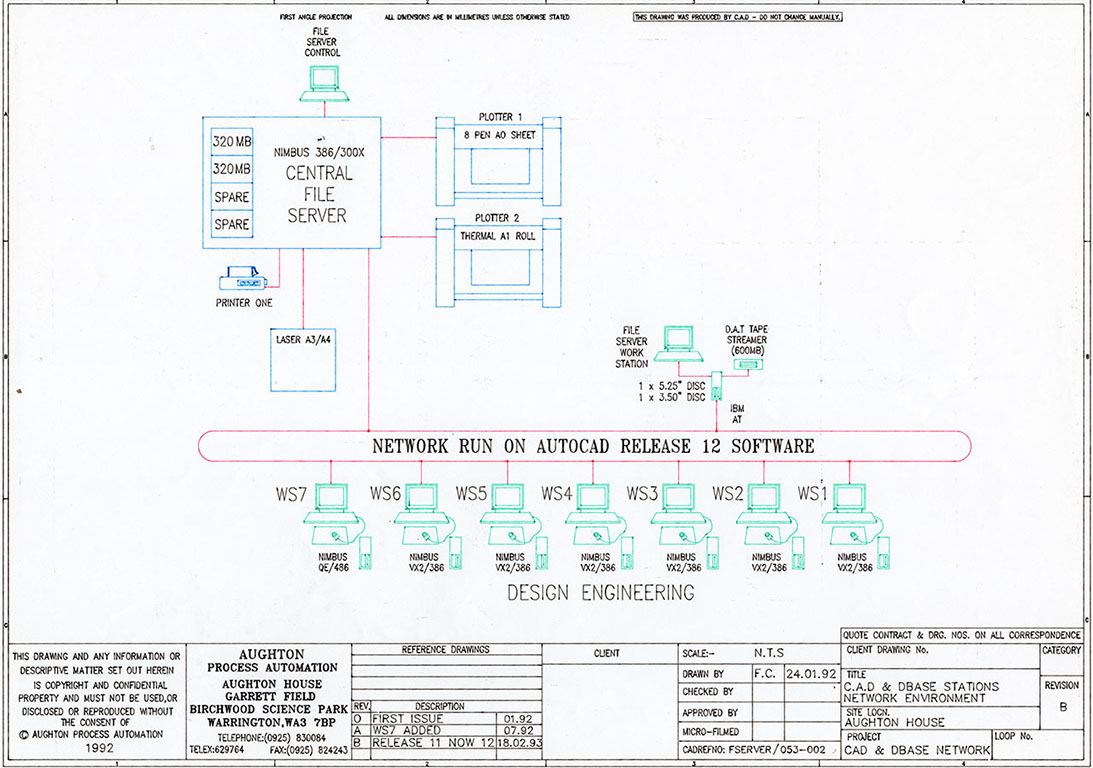

1991

Aughton invested in state of the art, computer-aided design systems, which included seven 386 personal computers!

-

1992

Aughton is accredited with the coveted BS5750 Part 1.

-

1993

A turbine control panel replacement is designed for the existing footprints of the old ones at Marsa power station.

-

1994

The Aughton team clock up 500,000 man-hours without incurring a lost-time accident at the Shell site.

-

1995

North West Water’s Rivington water treatment works was effectively automated by Aughton, who also supplied all field instruments and motor control centres.

-

1996

It was nothing to do with washing powder, and people still say that they have never heard of it.

-

1997

Aughton undertake a complete overhaul of the intelligent power trolley system, which they had installed eight years earlier at the Ford motor company.

-

1998

Aughton Hire achieves a record increase in turnover. Sceptics said that it was due to featuring a monkey on the front cover of the catalogue.

-

1999

Aughton complete the handover of Wybersley Water Treatment works for North West Water, comprising of all electrical distribution and instrument control systems.

-

2000

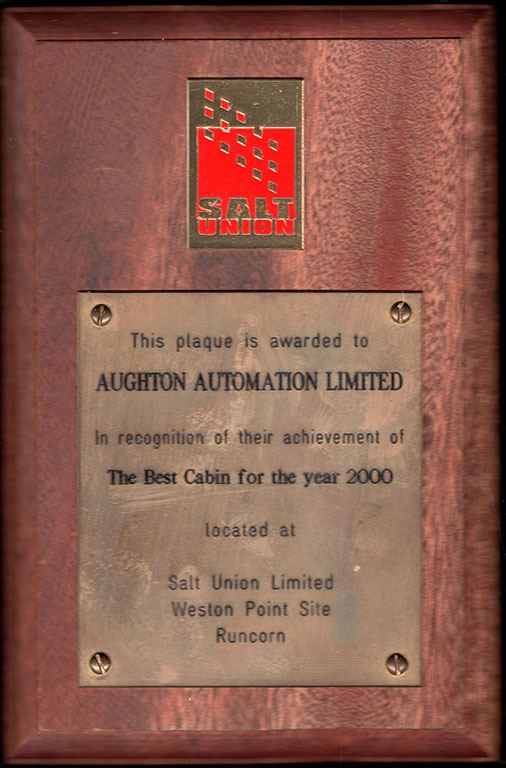

Aughton is awarded “Best Cabin of the Year” for it’s housekeeping, hygiene and practical layout. The Aughton team based at the Salt Union site in Runcorn were unaware that Salt staff were inspecting and auditing the 42 site-based contractor’s cabins.

-

2001

Aughton Hire takes off with the ‘Rental Odyssey’ edition of the Test Equipment Catalogue.

-

2002

Billy Durband has a retirement do’ at Childwall golf club.

-

2003

Aughton provides shift electrical and instrumentation teams to carry out the major shutdown overhauls for ICI.

-

2004

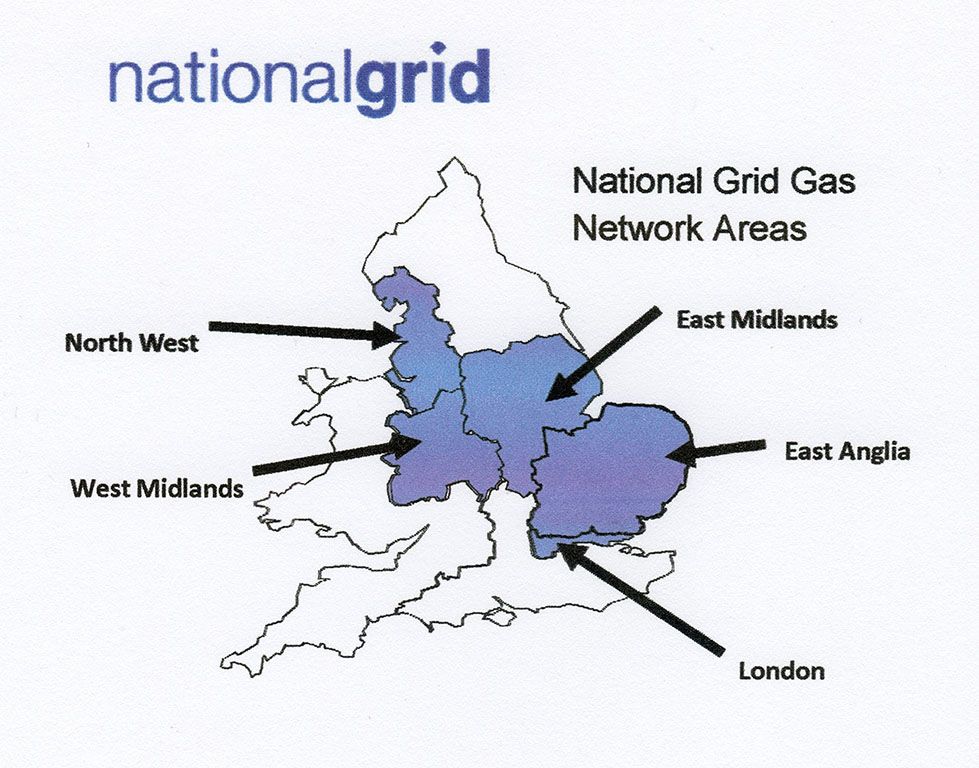

Aughton is awarded an eight-year electrical and instrumentation maintenance contract from British Gas Transco.

-

2005

Aughton complete another firearms training facility. Some projects are restricted information, but we are allowed to list the following clients : South Wales Police, West Midlands Police, Northern Ireland Prison Service, Cumbria Police, Isle of Man Constabulary, Military Training Establishment (South Coast), and various forensic facilities.

-

2006

Aughton provide the main electrical, instrument and mechanical resources to overhaul the 5J Chiller plant.

-

2007

Aughton complete a full schedule of hazardous area inspections for Eli Lilly on all plants.

-

2008

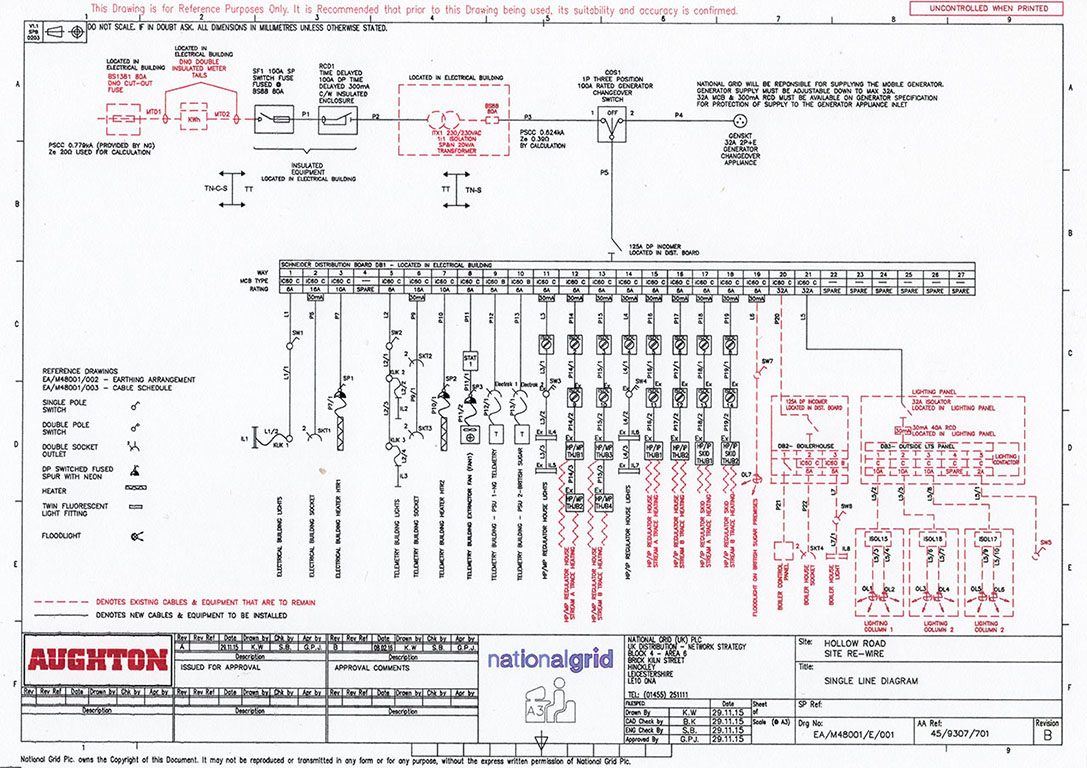

Aughton pre-fab & prepare over 200 instrument back-plates for the National Grid, ready for installation at sites all over the networks.

-

2009

Aughton celebrates its 40th anniversary.

-

2010

In order to achieve additional workshop and office space, Aughton purchases new premises at 115 Evans Road, Speke, Liverpool L24 9PB. The re-location was completed by early May.

-

2011

Aughton are awarded another Framework Agreement by the National Grid for electrical & instrumentation design, and installation projects.

-

2012

Aughton complete another bio-gas control system for the utilities sector.

-

2013

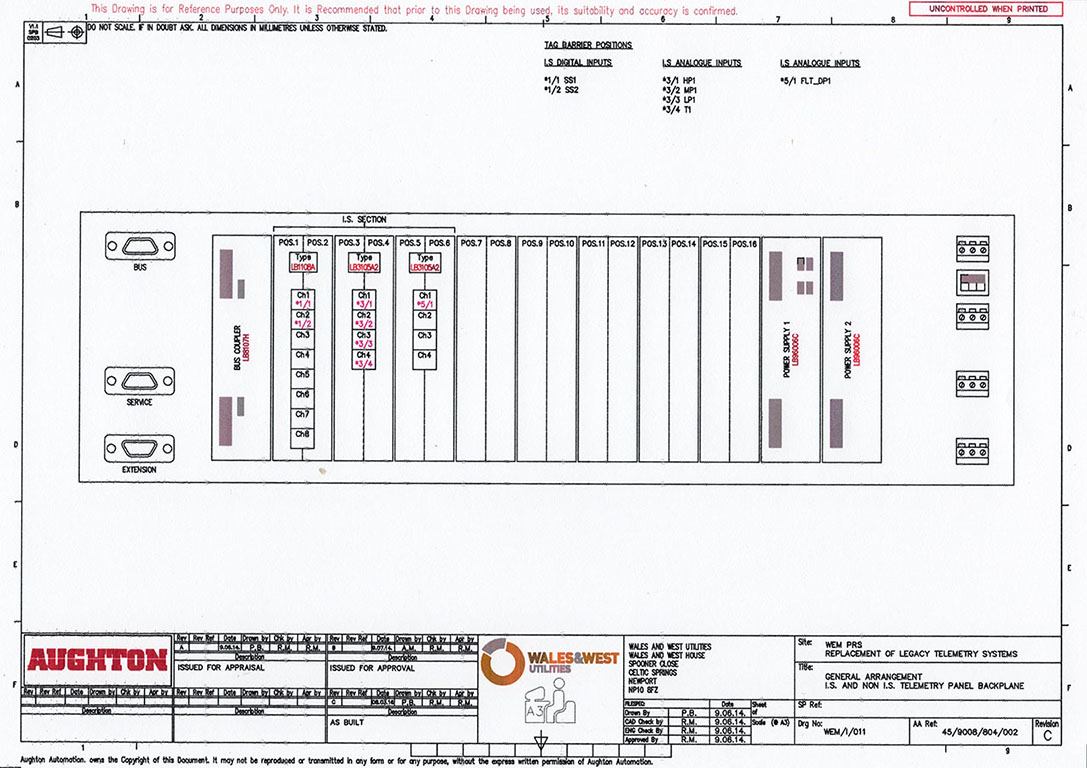

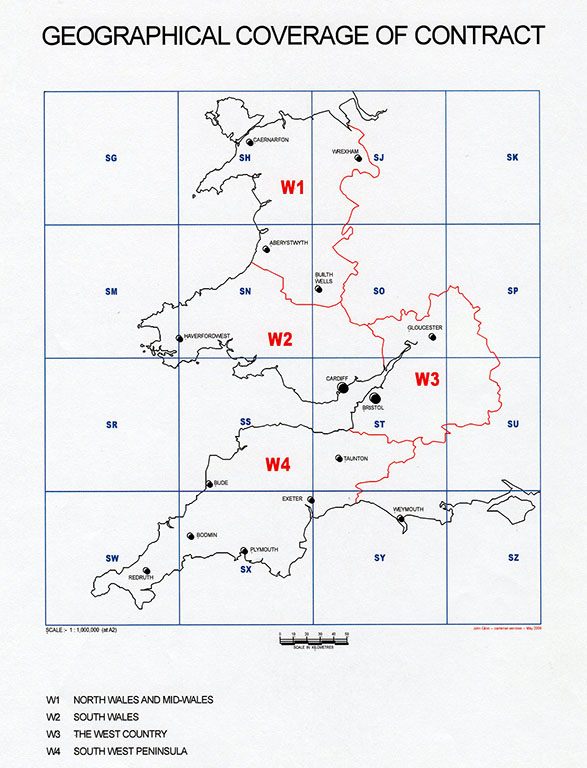

Aughton are awarded another Framework by Wales & West Utilities to provide design, build, installation, and consultancy services for all electrical & instrumentation disciplines.

-

2014

Aughton are awarded another two long-term Framework Agreements from the National Grid Gas PLC for the provision of operational and maintenance resources, and emergency and repair resources in all network areas. Aughton are proud to be associated with National Grid Gas since 1997 (then called Transco).

-

2015

Aughton was awarded another long-term Services Agreement by Wales & West Utilities for the provision of electrical, instrument, and mechanical operatives to support all areas. Aughton is proud to be associated with WWU since their incorporation in 2004.

-

2016

Aughton works in partnership with both National Grid and Vodafone on the Gas Remote Site Communications

-

2017

Aughton is awarded the Cadent At Height Comm’s Rationalisation Project in safe removal and disposal of existing / redundant communications equipment across a number of Cadent Gas Distribution sites throughout the UK.

-

2018

Aughton Achieves 100% in all areas on their Achilles UVDB Audit for the second connective year.

-

2019

Aughton acted as Principal Designer Principal Contractor for Britain’s largest Gas Distribution Network to deliver their first solar farm. 388 solar panels will generate an estimated 120 MW hours / year which will provide a clean and renewable source of energy.